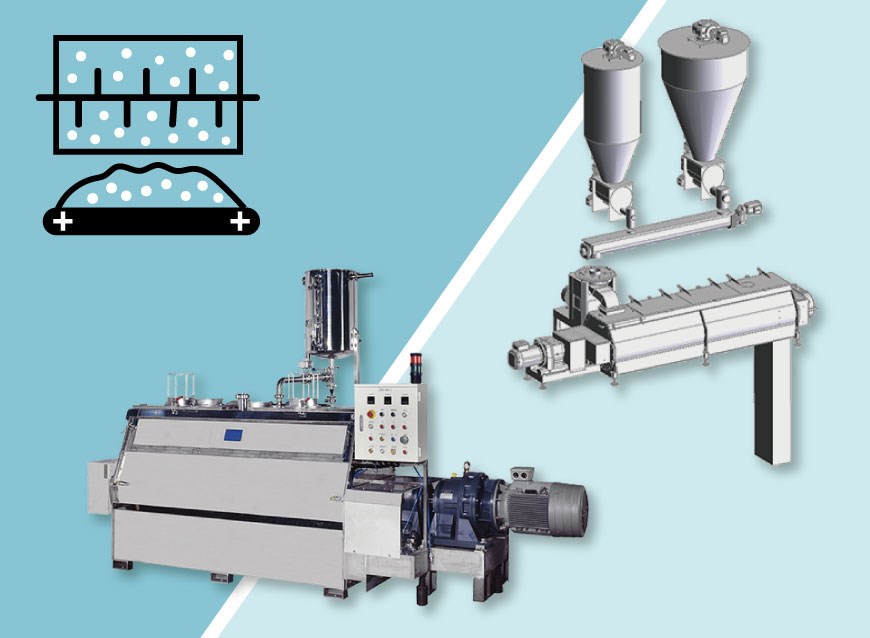

There are two options of flour mixing for the instant noodle production line: Batch Type, or Continuous Type. Traditionally, the flour mixing is mainly done by the Batch Type Mixers, the dough is made in batches and two mixers take turns to make the dough. Later on, following the advancement of automation technology, the fully automated Continuous Mixer is developed, which can produce dough continuously without interruption. Please refer to the comparison list below to determine the suitable mixing method for your instant noodle production line.

| Batch Mixer | Continuous Mixer | |

| Equipment Cost | ✔ Lower cost | The cost varies depending on the numbers of ingredient powder. |

| Space Required | ✔ Requires smaller space | Requires a certain height with more space. |

| Power | High power, high energy consumption | ✔ Less power, less energy consumption |

| Dough Temperature | 5~8°C temperature increase after mixing. | ✔ Only 1~2°C temperature increase after mixing. |

| Mixing Result | Mixing performance of flour & kansui (lye water) is limited by the spray nozzle. | ✔ The Rotatory Mixer can mix the flour and kansui completely and improve the uniformity of water in the dough. |

| Operation | Every batch of mixing and discharging needs to be activated from the control panel. | ✔ Higher level of automation. After starting, the operator can check the dough texture and moisture right away, and adjust the ratio accordingly. |