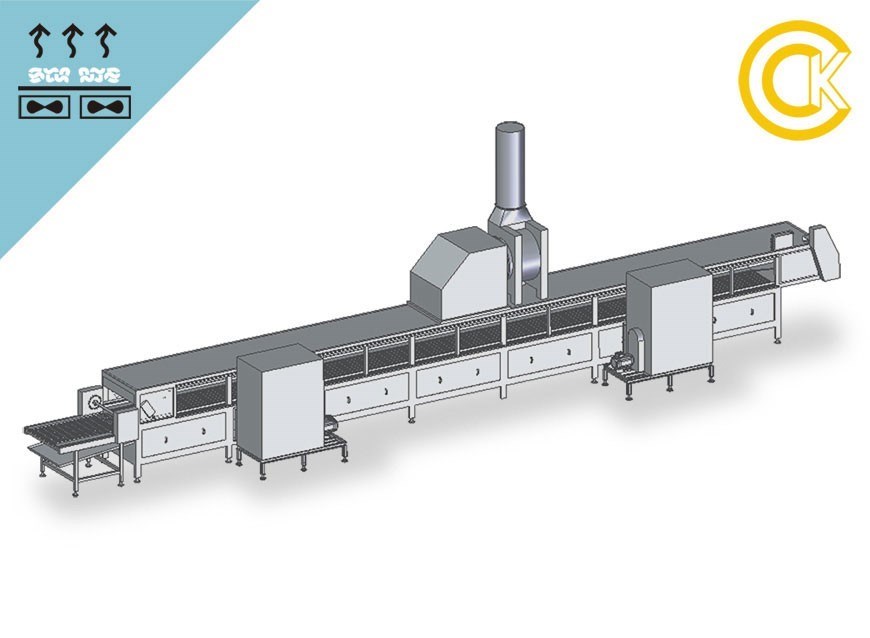

The Conveyor Cooler consist of one Bar Conveyor, one Cooling Conveyor with pushing rods, the cooling chamber, Blowers and Exhaust Blower(s). The Bar Conveyor organizes and transfers the noodle blocks into the Conveyor Cooler. The Blowers are fitted with filters and draws air into the cooling chamber to cool down the fried noodle blocks. The hot air is exhausted through the Exhaust Blower(s) on the top of Conveyor Cooler. The center of the fried noodle blocks after frying may usually reach over 100°C. After cooling, the noodle temperature drops down to 36°C, and then are transferred to the next processing stations for packaging and storage.

FEATURES

● Hygiene: All area that has direct contact with food product is made of stainless steel or food grade materials.

● Cleaning doors are provided for the top chamber and the bottom chamber.

● Blower Filters are mesh type made from stainless steel, and can be washed and used repeatedly.

● The Conveyor Cooler uses pushing rods of stainless steel instead of plastic trays to extend the life of the parts.

PROCEDURE

● Once the noodles reach to the Cooler, operator observes the transfer of noodle blocks. During production, the operator takes samples to monitor the noodle temperature and the moisture content depending on the production requirement from the client factory.